Repair performance testing is a critical process ensuring car repairs meet safety standards and customer expectations. This meticulous evaluation includes scrutinizing mechanical, structural, and aesthetic aspects, such as paint color accuracy and dent removal precision, to guarantee quality under real-world conditions. Guided by safety regulations, these tests confirm repairs, from bumper repairs to structural components, meet or exceed industry standards for strength, durability, and integrity. By adhering to these standards, repair performance testing enhances vehicle safety, fosters public trust, and offers auto repair businesses advantages like reduced liability, improved customer satisfaction, and operational efficiency.

In today’s safety-conscious landscape, effective repair performance testing is not just a best practice but a regulatory requirement. This article delves into the intricate relationship between repair performance testing and safety regulations, offering a comprehensive overview of understanding test methodologies. We explore how these tests ensure vehicle safety standards are met, aligning with best practices to benefit both industries and consumers. By navigating this process, we uncover key strategies to revolutionize automotive safety protocols.

- Understanding Repair Performance Testing: A Comprehensive Overview

- The Role of Safety Regulations in the Testing Process

- Aligning Repair Performance Testing with Safety Standards: Best Practices and Benefits

Understanding Repair Performance Testing: A Comprehensive Overview

Repair performance testing is a critical process that evaluates the effectiveness and efficiency of car repair services. It involves assessing various aspects of a vehicle’s restoration to ensure it meets safety standards and customer expectations. This comprehensive evaluation goes beyond mere visual inspections, delving into the mechanical, structural, and aesthetic elements of car dent repair and car paint services.

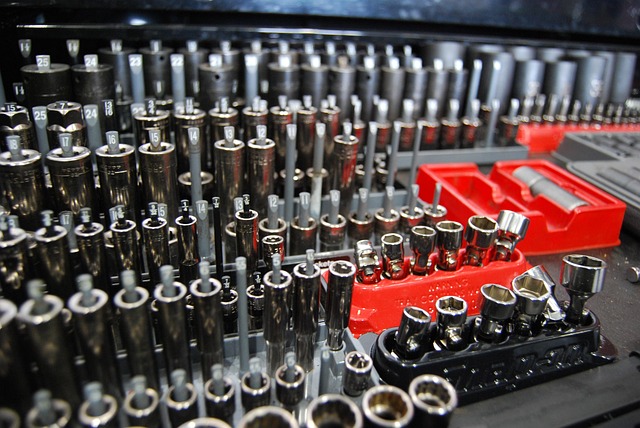

The testing methodology includes a series of rigorous checks and simulations designed to replicate real-world conditions. For instance, in car paint services, this might involve checking color accuracy, gloss levels, and resistance to fading or chipping. Similarly, car dent repair performance testing assesses the quality of repairs by measuring precision, structural integrity, and the minimality of residual dents or blemishes. This meticulous approach guarantees that every aspect of the repair process aligns with industry standards, ensuring customer satisfaction and road safety.

The Role of Safety Regulations in the Testing Process

Safety regulations play a pivotal role in shaping the testing process for repair performance, ensuring that all repairs meet stringent standards to protect both vehicle integrity and occupants’ safety. These regulations are designed to guide mechanics and repair facilities on acceptable practices, materials, and techniques for various car body restoration and collision repair procedures. Adhering to these guidelines is not just a legal requirement but also guarantees the long-term reliability and safety of vehicles post-repair.

The testing process involves rigorous evaluations to confirm that each repair, from bumper repair to more complex structural components, meets or exceeds industry standards. This includes assessments for strength, durability, and structural integrity, ensuring vehicles can withstand potential future collisions. By aligning with safety regulations, repair performance testing becomes a critical tool in maintaining vehicle safety, fostering public trust, and promoting quality collision repair services.

Aligning Repair Performance Testing with Safety Standards: Best Practices and Benefits

Repair Performance Testing plays a pivotal role in ensuring that auto glass repair, tire services, and car paint repair processes meet stringent safety standards. By aligning these tests with relevant regulations, businesses can mitigate risks, enhance quality control, and ultimately protect end-users. Best practices involve integrating comprehensive testing protocols at every stage of the repair process. This includes pre- and post-testing to gauge the effectiveness of repairs, utilizing specialized equipment for precise measurements, and regularly calibrating tools to maintain accuracy.

Benefits are multifaceted: improved safety, reduced liability, enhanced customer satisfaction, and operational efficiency. Testing ensures that replaced parts meet original specifications, preventing subpar repairs that could compromise vehicle integrity and safety. By adhering to these best practices, repair facilities can foster trust among customers, comply with legal mandates, and maintain a competitive edge in an industry where safety is paramount.

Repair performance testing is a critical process that aligns seamlessly with safety regulations, ensuring vehicles meet stringent standards. By integrating comprehensive testing methods, manufacturers can identify and rectify potential issues, enhancing overall vehicle safety. This strategic approach not only complies with legal requirements but also builds consumer trust, demonstrating a commitment to delivering reliable and secure automotive solutions. Repair performance testing, when conducted effectively, serves as a powerful tool in the ongoing pursuit of safer transportation.