Repair performance testing is a critical process in auto maintenance, ensuring vehicle repairs meet quality and safety standards. Using advanced tools like 3D measuring equipment, it verifies structural integrity, functionality, and aesthetic restoration after damages. This rigorous evaluation prevents costly issues by simulating real-world conditions, allowing for the validation of new safety features and modifications. Best practices involve tailored test protocols, regular training, automated systems, and thorough documentation to enhance efficiency, reduce errors, and build customer trust in reliable, safe, and durable repairs.

“Repair Performance Testing (RPT) is a proactive approach that ensures product reliability by identifying and rectifying potential issues before they resurface. This comprehensive method involves simulating real-world scenarios to assess a product’s performance after repairs.

By understanding RPT, we can emphasize prevention in repair strategies, minimizing the need for repeated fixes. This article explores the significance of RPT, offering insights into best practices for its effective implementation, ultimately enhancing overall product quality and customer satisfaction.”

- Understanding Repair Performance Testing

- The Role of Prevention in Repair Strategies

- Best Practices for Effective Implementation

Understanding Repair Performance Testing

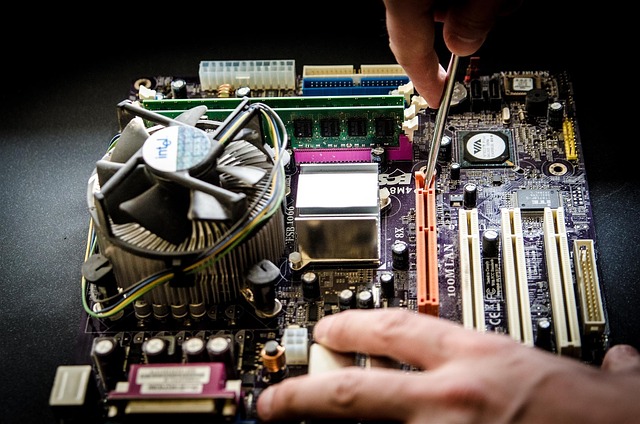

Repair performance testing is a critical process that evaluates the effectiveness of a vehicle’s repair against established standards and previous issues. It goes beyond simple visual inspection by employing various methods to assess structural integrity, functionality, and aesthetic restoration after a car collision or auto dent repair. This involves using specialized equipment, such as 3D measuring tools, to ensure repairs are precise and meet manufacturer specifications.

During these tests, the focus is on validating that the vehicle’s performance, safety features, and overall quality are not compromised by previous repairs, especially in cases of complex car collision repair or intricate auto dent repair tasks. The data gathered provides insights for continuous improvement in repair techniques and materials, ultimately preventing future issues and ensuring customer satisfaction with the vehicle repair process.

The Role of Prevention in Repair Strategies

In the realm of auto maintenance, especially within collision repair shops, prevention is key to ensuring long-lasting solutions. Repair performance testing plays a pivotal role in this strategy by identifying potential issues before they escalate into costly and time-consuming repairs. By simulating real-world scenarios and stress-testing vehicles, these tests uncover hidden weaknesses or vulnerabilities that might go unnoticed during regular checks. This proactive approach allows auto collision repair professionals to address problems early, preventing them from recurring.

For instance, a collision repair shop can utilize repair performance testing to validate the strength of newly implemented safety features or the effectiveness of recent structural modifications. Such rigorous testing not only safeguards against future accidents but also enhances the overall quality of auto collision repair services. This is particularly crucial in an industry where customer trust and satisfaction are built on reliable, safe, and durable repairs.

Best Practices for Effective Implementation

Implementing effective repair performance testing is a strategic move to prevent recurring issues in collision repair or vehicle repair services. The best practices involve establishing comprehensive test protocols tailored to specific procedures, such as paintless dent repair (PDR), ensuring every stage of the repair process is rigorously evaluated. Regular training sessions for technicians on the latest testing methods and tools are essential to maintaining high standards.

Moreover, integrating automated testing systems can significantly enhance efficiency while reducing human error. Continuous monitoring of repair quality through these tests allows for immediate identification of problematic areas, enabling quick adjustments. This proactive approach, combined with thorough documentation, creates a robust system that guarantees the consistency and reliability of vehicle repair services, ultimately leading to satisfied customers.

Repair Performance Testing is a proactive approach that plays a pivotal role in preventing recurring repair issues. By simulating real-world scenarios and evaluating system resilience, organizations can identify weaknesses before they cause disruptions. Implementing this testing as a standard practice within maintenance strategies ensures a more reliable and efficient service delivery, ultimately enhancing customer satisfaction. Adhering to best practices, such as comprehensive testing plans and regular updates, reinforces the effectiveness of repair performance testing as a game-changer in predictive maintenance.